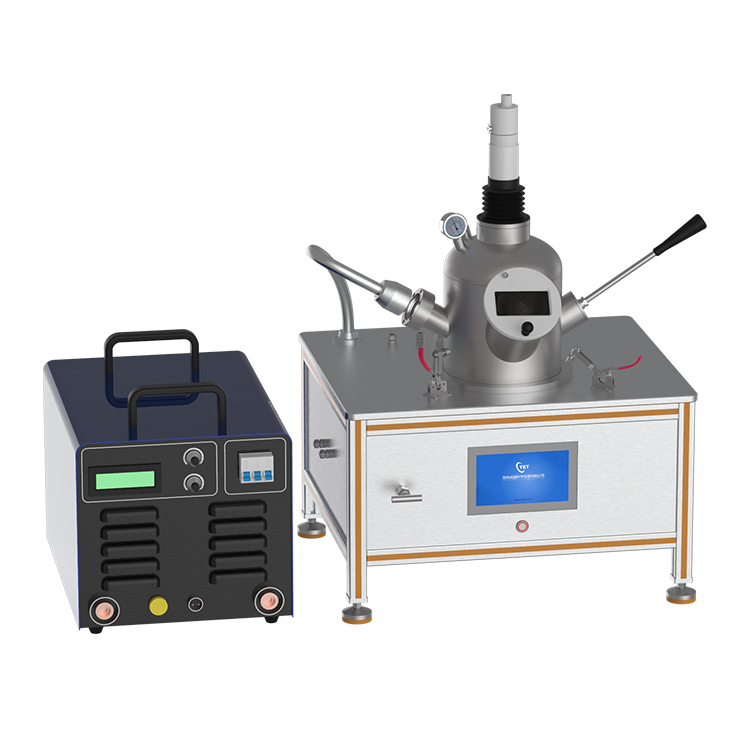

1. Arc melting chamber: φ200mm × 300mm. The surface of high-quality stainless steel is selected for electrochemical treatment. 2. Melting sample: weight ≤15g (calibrated with stainless steel) / per melting cavity, total 4 melting working stations. 3. Pipe sealing station: can weld the tantalum tube diameter φ5-φ14mm, length 50-100mm; station rotation automatically, speed can be adjusted 0-45rpm. 4. Vacuum degree: The standard mechanical pump is 6.0E-1Pa. If another molecular pump can reach 5.0E-3Pa (the vacuum gauge is not provided as standard) 5. Arc starting mode: high frequency arc starting. 6. Rated input power: 10.4 KVA 7. Cooling method: circulating water cooling |